<

Serge77 - My Rocket Workshop >Preparation of KNO3-Sorbitol Propellant

in Copper Cap

Short summary:

The possibility of influence of copper as vessel material on the process of KNO3-Sorbitol propellant manufacturing is studied.

Starting materials:

Sorbitol: pharmaceutical grade. Moisture content 0.2-0.3%.

KNO3: reagent grade "pure for analysis". Moisture content 0.1-0.2%.

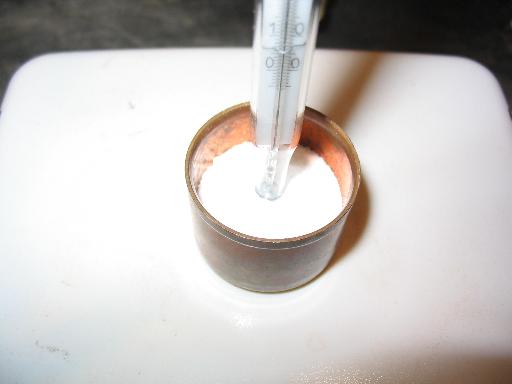

Copper cap: copper endcap for copper pipes, OD = 30 mm, H = 22 mm:

Evaporation of water KNO3 solution

3 g of KNO3 and 3 g of water were heated upto gentle boiling. After complete evaporation KNO3 was dissolved in water (sol-1) and compared with solution of pure KNO3 (sol-2) of the same concentration. Sol-2 was clear colorless liquid. Sol-1 was very slightly yellow very slightly turbid liquid (at right on the photo). Then ammonia solution was added to the sol-1 and sol-2. Sol-2 remained clear colorless liquid. Sol-1 become very slightly blue liquid (copper-ammonia complex is deep-blue). Therefore KNO3 contains some very small copper impurity after evaporation in copper cap.

Melting of sorbitol

Sorbitol was melted in copper cap and kept at 150-160C 4 hours.

Copper surface under sorbitol melt become shiny, so thin copper oxide layer was dissolved or reduced.

Resulting sorbitol (S-2) was compared with starting pure sorbitol (S-1) and sorbitol (S-3), which was heated at 150-160C 4 hours in glass beaker. Photo, left to right: 50% water solutions of S-1, S-2, S-3. There are no visible difference between S-2 and S-3. Addition of ammonia solution to S-2 did not result in visible color change.

Melting of KNO3-sorbitol 65-35 mixture

2 g of KNO3-sorbitol 65-35 mixture was melted in copper cap and kept at 150-160C 4 hours with occasional stirring. Then mixture was cooled to 100C and 2 g of water was added, resulting in brown solution. Addition of ammonia solution did not results in visible color change.

Small amount of copper oxide grew just above the propellant level. It can be easily wiped with paper.

2 g of KNO3-sorbitol 65-35 mixture, which was heated at 150-160C 4 hours in glass beaker, developed only light-yellow color, very similar to sorbitol, heated in glass beaker.

Conclusions.

Prolonged heating of KNSB propellant in copper vessel lead to slow corrosion of copper and decomposition of sorbitol. Possible reaction pathway for this process may be the following: oxidation of copper by KNO3 and/or oxygen, then reduction of Cu(I) and/or Cu(II) compounds with sorbitol. It is very similar to industrial process of oxidation of alcohols to ketones by oxygen on copper catalyst.

Amount of copper, dissolved in propellant, is very low. It can be estimated in the order of 0.01%.

20.04.2006 Serge77