< Serge77 - My Rocketworkshop >

NOZZLELESS ROCKET MOTORS

some theory and my results

Nozzleless motors are used in industry and are well described

in the literature. This is quote from Timnat Y.M., Advanced

Chemical Rocket Propulsion, Academic Press, London, 1987, Chap.

6:

"The simplicity, reliability and cost effectivenes due to

the avoidance of a nozzle, the simple propellant configuration

and the reduced insulation requirements, make the nozzleless

rocket motors an attractive concept in spite of its lower

specific impulse (by about 20%) compared to nozzled motors. In

addition, the elimination of the nozzle assembly is used to

increase the overall amount of propellant, that, in most

instances, can compensate for the reduced performance."

Interesting paper: "Internal Ballistics Considerations of Nozzleless Rocket Motors", Journal of Propulsion and Power, 1999. The main idea, confirmed by experiment and calculations: the burning speed of propellant is approximately the same along the entire length of the core, because the acceleration of combustion due to erosion near the nozzle is compensated by the acceleration of combustion in the head part due to a much higher pressure than near the nozzle.

Nozzleless motors are very suitable for amateurs, due to their

simplicity of manufacture and sufficiently high characteristics.

Their pros are:

- simplicity of manufacture

- high propellant mass fraction

- high reliability

- trouble-free ignition due to the simple shape of the core (if

done correctly)

- slightly less dangerous consequences of CATO.

However, 10-15 years ago almost no one use them, perhaps the only examples are 75 and 125 mm caliber motors with APCP propellant. More compact versions of the video can be downloaded here: 75 mm, 125 mm. There was no information available about candy nozzleless motors, therefore I began to investigate them.

Candy propellants are particularly suitable for these motors, because they stably burns at any pressure, unlike composite propellants. Another important nuance - candy is very rigid, so all pressure in the motor is kept by the propellant itself, the strength of the casing is practically irrelevant, it can be thin and light. Therefore, the strength of the fuel itself becomes very important. I have measured the strength of different candy propellants, the most strong appeared to be KNSB, so I use it most often for these motors.

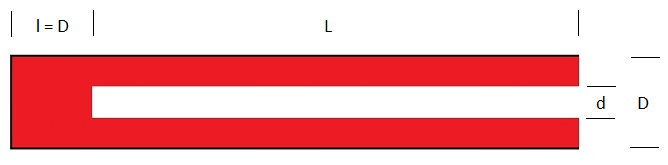

The motor construction can be of two types - with an inert bulkhead (top in the picture) and with bulkhead from the propellant (the lower one in the picture). I have made both types, they all work. Inert bulkhead should be very rigid, like propellant, and have good adhesion to propellant.

The first experiments were made in 2004-2005, they were unsuccessful due to improper ignition. I used Secondary Ignition Composition SIC-1, stretched along the core, as I did in the nozzle engines. However, it was very quickly ejected from the core by its own gases, and so propellant was ignited only at the exit from the core, if at all. When using a conventional igniter, the same thing often happened, because sorbitol propellant requires a fairly powerful igniter and it also was often ejected out of the core. The first tested engine had a caliber of 38 mm and a core length of 340 mm, it burned on the test stand for 90 seconds, without giving any thrust of course. Then I began to press a tablet of KNO3-C composition (80-20) to the top of the core and all the problems disappeared.

The first successful test:

http://serge77-rocketry.net/nozzleless/nozzleless.htm

The engine with an inert bulkhead is made by pressing method,

which I have been using for making

propellant grains for a long time. This engine has a small

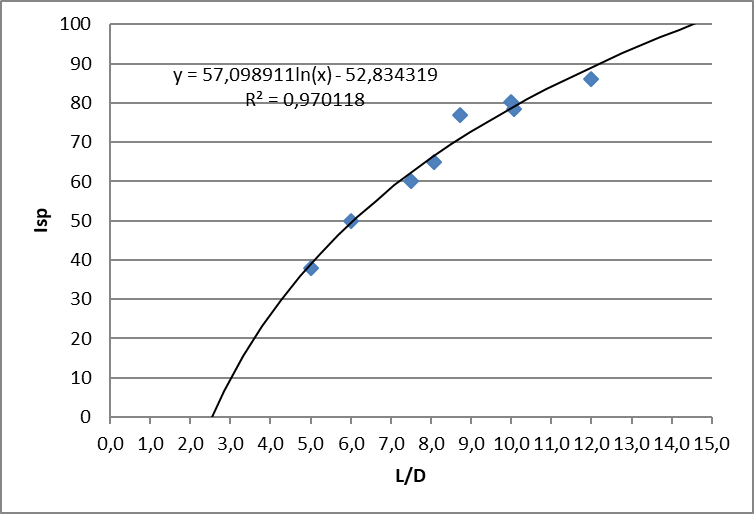

extension, L / D = 6 (the ratio of the length of the core to the

outer diameter of propellant), so the Isp is low, only 50 s.

After that other methods of motor making were tested:

http://serge77-rocketry.net/nozzleless2/nozzleless2.htm

http://serge77-rocketry.net/nozzleless3/nozzleless3.htm

http://serge77-rocketry.net/nozzleless4/nozzleless4.htm

http://serge77-rocketry.net/nozzleless5/nozzleless5.htm

http://serge77-rocketry.net/nozzleless6/nozzleless6.htm

The last method is the most simple and convenient, I use it now

for 50 mm motors.

After my experiments, nozzleless motors became widely and

successfully used, for example, our Kiev rocket group launch

almost all its rockets on such engines. Most of my friends forgot

about nozzles now).

The obtained data allow to compare the efficiency of the

nozzleless and nozzle engines.

Paper and plastic nozzled motors working at low pressure give the same

Isp, but they have more weight and are more difficult to

manufacture, so they completely concede to the nozzleless.

Metal nozzled motors works at higher pressure and have a higher Isp, but

at the same total motor weight they give the same or only

slightly larger total impulse at the expense of a heavy casing,

i.e. no winnings here or it is quite small.

Only high-tech glass/carbon-fiber or aluminum engines with

efficient nozzle, working at high pressure, are noticeably

winning.

Therefore, I advise all beginners, and not only beginners - go

nozzleless!))

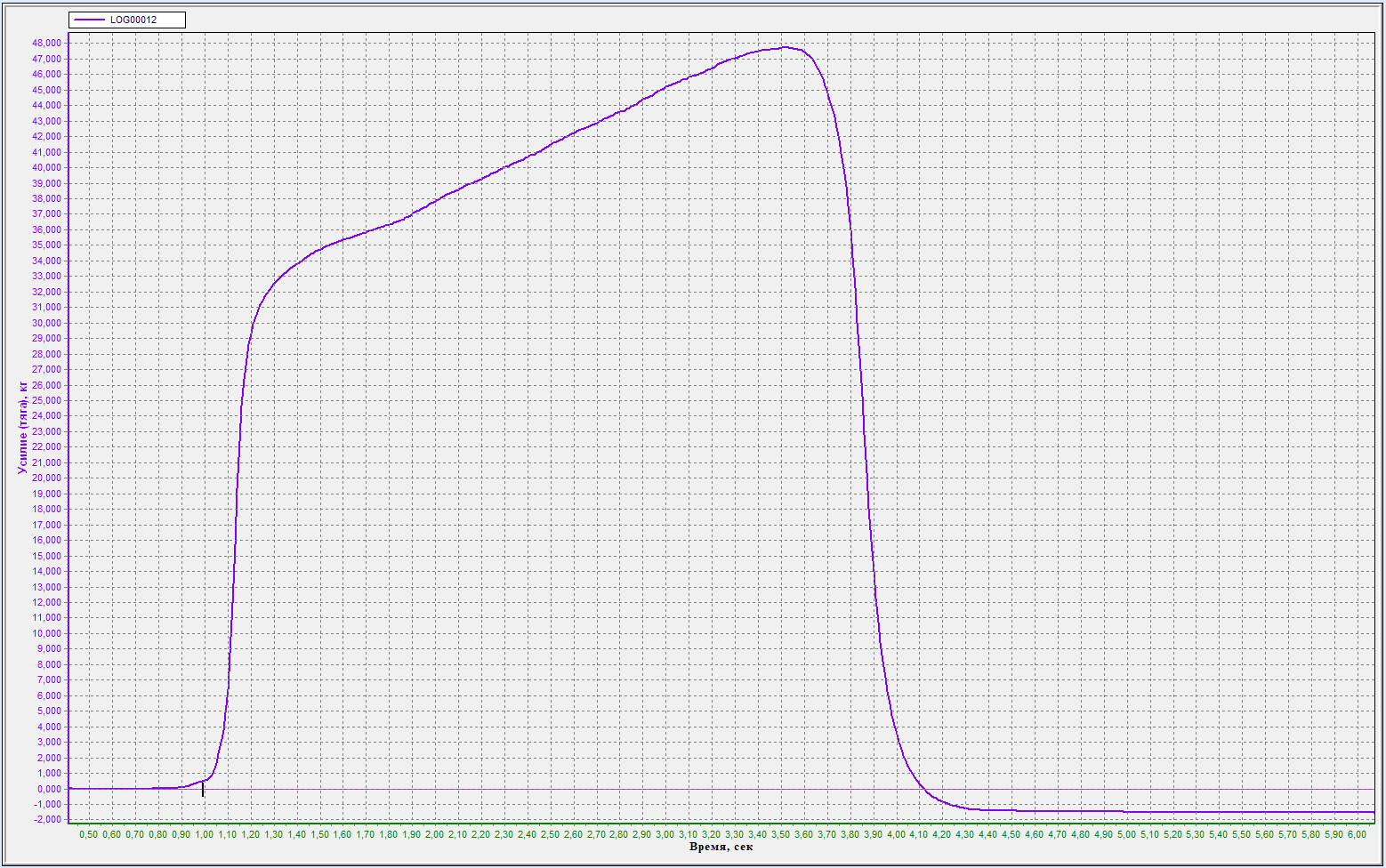

Test stand data analysis

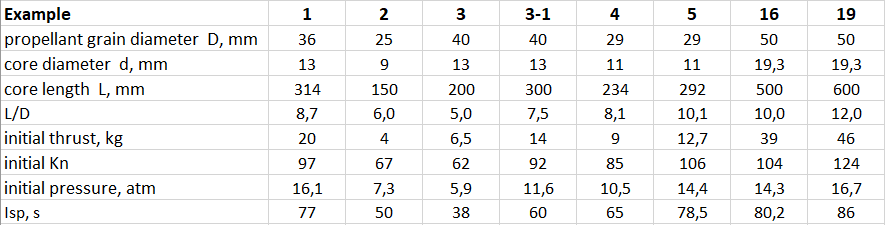

In this table, the data of most of the tested engines are collected:

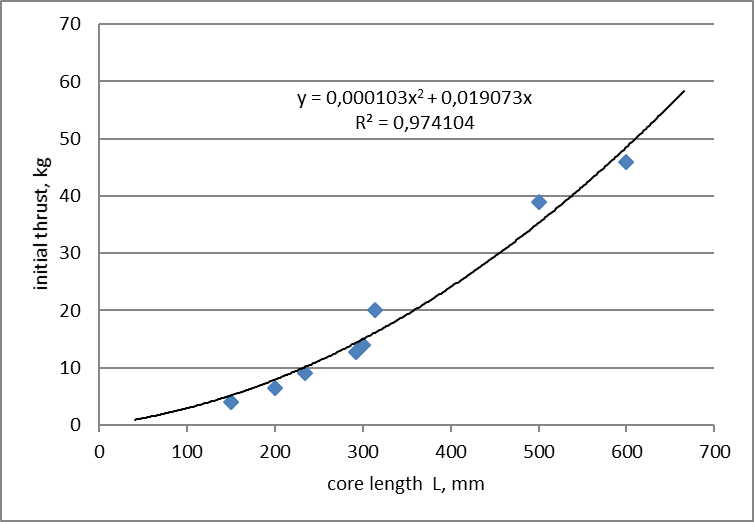

There are somewhat different propellants here, but their burning

rates are approximately equal. There are also different designs -

with an inert bulkhead and a bulkhead from the propellant. But it

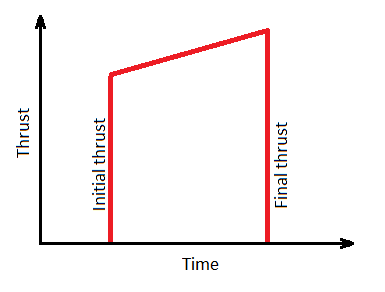

is still clear that the dependence of the initial thrust on the

channel length fits well into the quadratic dependence, as it

should be in theory. According to the equation on the graph, one

can calculate the thrust of the newly designed motor.

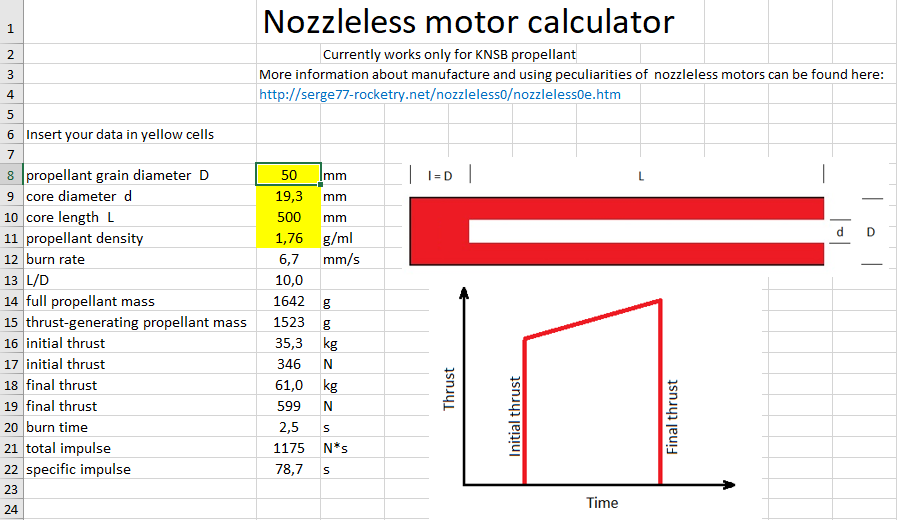

Based on obtained data,

a program for nozzleless motor design was developed:

nozzleless.xls

It allows you to calculate the initial and final thrust, operating time, total and specific impulse of the engine. Calculated data are in good agreement with the practically measured parameters.

Recommendations

18.11.2007 - 24.10.2017 - 16.10.2020 Serge77